Synergy is an industry leading specialist in water treatment with proven success in a wide range of contaminants including metals, hydrocarbons, PFAS and organics. Synergy's inhouse capabilities include the design, manufacture, operation and maintenance of multibarrier Water Treatment Plants (WTPs).

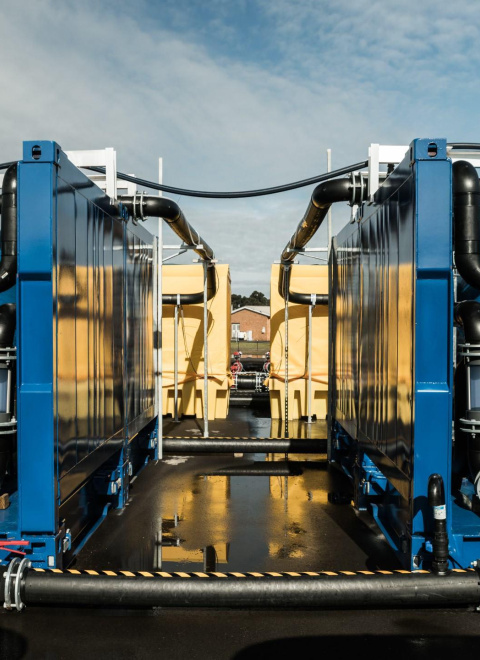

Our modular equipment is easily transportable, enabling us to create tailor-made bespoke treatment solutions for any size project to target specific pollutants. Flowrates can range from 1 litre per second up to 90 litres per second depending on site requirements.